Vintex Products

New, Lower-Cost Material Handling Products – KRC2, V-Clear2 & Vu-Thru2

Vintex is well known for high-quality composite material handling products and we are pleased to introduce a new lineup of lower-cost automotive material handling options. These new materials give automotive packaging manufacturers and returnable dunnage design engineers added choices when looking for soft, durable, fabrics they can trust. The benefits are a better value point for cost sensitive projects without having to compromise on performance.

Every manufacturer wants to use the best products available at a competitive price. So, when Vintex looked at its material offerings, we wanted to give customers more flexibility and choices in deciding between “Good, Better, Best”.

Expanding our product offering allows customers to take advantage of all the benefits of dealing with a trusted supplier for volume pricing, consolidated shipping, quick delivery, technical support and of course, the high-level of service that can always be expected from Vintex.

.

We are pleased to introduce the new additions to our line as follows:

KRC2

A new soft, brushed Tricot face offers excellent protection to any Class-A surface. Tested for scratch resistance against sensitive parts, this new composite face fabric outperforms competing products while maintaining the same weight and strength properties of standard KRC. Currently available in grey with a tan and blue option in development for early 2021.

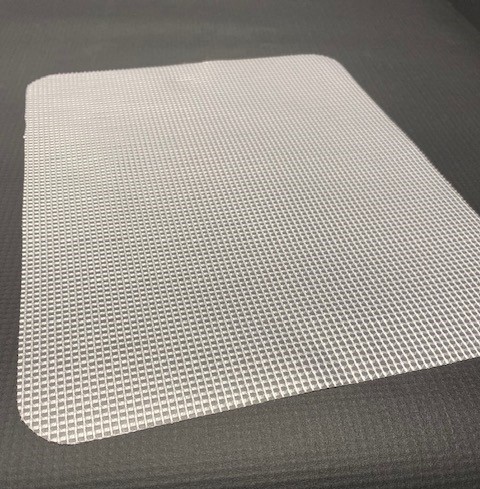

V-Clear2

Newly formulated to create a crisp blue tint with improved clarity, V-Clear2 introduces a new 2×2 scrim matrix with wider openings for better transparency without sacrificing any strength or durability properties. Available in 13, 18 and 27oz, this newly designed formulation offers an attractive price point perfectly suited for indoor curtain, cover and flap applications.

Vu-Thru2

A cool blue tint gives Vu-Thru2 a modern look and feel for any dunnage bag application. Our new PVC formulation provides a smooth-glide surface to help parts slide in and out of packaging. In addition, a slightly firmer hand adds pocket support and shape structure for long term performance.

All three new fabrics are manufactured exclusively at Vintex’s Mount Forest, Ontario production facility and have been engineered to meet today’s essential automotive standards. These new products have been added to the portfolio of our existing products, creating the industry’s most comprehensive assortment of material handling fabric options.

.

Please contact our Inside Sales Rep, Alison Marchant, to find out more:

Alison.marchant@vintex.com

.

What’s Next?

New Material Handling Tote and Bin Liners

Vintex is currently developing a new line of TAB Liners (Tote And Bin) engineered specifically to line rigid containers and protect Class-A parts with a soft and affordable sewable fabric. Trials are currently underway and initial customer feedback on prototypes and usability has been great! Please call for additional information and stay tuned for product release in early 2021.

.

.

Jamie Goodfellow

SVP, Corporate Development

DINP and California Proposition 65 Summary

What is California Proposition 65?

Proposition 65 is “Right-to-Know” legislation intended to protect the public from exposure to certain substances that are suspected to cause cancer or reproductive harm. Information about Proposition 65 can be found via the following link: Proposition 65 Frequently Asked Questions

Proposition 65 applies to products sold in or imported into the State of California that contain one or more listed substances, and where public exposure to the substance(s) could be expected to exceed certain limits. There are currently more than 900 substances listed under the California Proposition 65 list.

Why was DINP added to the Proposition 65 List?

DINP was added to the Proposition 65 list at the end of 2013 based on a series of animal studies indicating that relatively high doses of DINP can cause tumors in rodents. However, this finding is not supported by extensive scientific data and analysis conducted by industry, the American Chemical Council, and multiple regulatory bodies in the USA, EU and Australia who recently found no relationship between DINP exposure and cancer in humans. No published studies of carcinogenic effects on humans were found.

DINP and Vintex products

In 2009, Vintex moved away from all phthalates (including DINP) in all our V-Care and SoffTICK healthcare formulations but we continue to use DINP (DINP Plasticizer – More Information) as a plasticizer in a number of formulations in our products such as:

- Athletic mats

- Ventilation ducting

- Material handling products

We expect that in most instances, the warning labels specified by Proposition 65 will not be required for vinyl-coated textiles formulated with DINP. Once the “safe harbor” limits are published (expected later in 2014) a more definitive answer will be provided.

Do I have to stop using products made with DINP?

No. California Proposition 65 does not prohibit the use of DINP in California. Depending on the application, the product may simply require a Proposition 65 warning label. Businesses supplying the California market can decide for themselves if they wish to continue to use products that contain DINP. Contact Vintex for more information on alternatives.

Do I have to put a Proposition 65 warning label on my product?

Maybe. For products that contain DINP, the regulation comes into effect in December 2014. The regulation is not based on DINP content, but on the DINP exposure to the public that would be expected to result from normal uses of the product. At this time, the acceptable exposure limit is not known, but there are indications that this information will be available in late 2014. However, until this information is published, and until manufacturers conduct the exposure estimates, there is no way to know for certain if warning labeling will be required. Vintex is working with our suppliers and with industry organizations to better understand the full implications of Proposition 65 on the use of DINP in flexible vinyl products. For more information, please view

Paul Hruska Manager – Regulatory Compliance

Vintex Inc.

Uniply Lite: The Superior Bonded Bed Pad

Institutional laundry environments can be harsh, with the expectation the bed pad needs to endure all conditions whether or not these are regular or isolated circumstances.

Challenges for heavily soiled bed pads can include:

- chlorine bleach pre and re-wash

- heavy duty strike extractor technology

- long pad-life or misuse such as, faulty equipment, batch contamination, and/or process miscalculations

Laundry Chemical Resistance

Vintex’s formulations and fabrics are proven technology for over 30 years. Uniply Lite is backed with a heritage of proven performance. Vintex PVC formulations proven to withstand multiple chemical environments

- demonstrated to withstand wide variety of commercial laundry chemical systems

- traditional chlorine sanitizing and or re/pre-wash

- conversion to peroxide or per-acidic systems

Durability

Vintex’s unique mechanical bonding process fuse various components of the bed pad together delivering up to 50% improved durability to alternatives

- substantial improvement over laminated construction

- provides inherent protection against adhesive decomposition and subsequent delamination

Endure Equipment Rigors

Improved laundry efficiencies, decreased cycle times

- demands on bed pad’s durability has increased

Tunnel washer / strike extractor improvements

- harsh mechanical environments have resulted

- demands on bed pad strength has increased

Field studies show a unique and verified performance advantage with Uniply Lite over urethane pads Uniply Lite offers superior resistance against strike extractor induced micro-bursts and leaks.

Failure Modes of Urethane Pads

Delamination

Strike extractor micro-burst

Thin Film gels

Leaks

Certified Safe Guard Barrier Systems

All Vintex V‐Care® and SoffTICK® products are now Certified Safe Guard Barrier Systems, meeting phthalate-free and lead‐free CPSIA guidelines.

In response to growing concerns in many healthcare and institutional settings over certain harmful or suspect chemical compounds, all V-Care and SoffTICK fabrics are now certified by Vintex to be manufactured to be free of lead, cadmium, mercury, arsenic and phthalates to the following levels:

| Phthalate Free | Manufactured without the use of phthalate plasticizers (DOP/DEHP, DBP, BBP, DINP, DIDP and DnOP) certified to contain less than 1,000 ppm per CPSIA guidelines, using GC-MS method. |

| Lead Free | Lead content of less than 10 ppm per ASTM-D-1976- 07 using EPA 3052 digestion. |

| Heavy Metal Free | Cadmium and Mercury content of less than 10 ppm, Arsenic content at less than 20 ppm,. per ASTM- D1976-07, using EPA 3052 digestion. |

Please be assured that these products have been lead and heavy metal free for many years, it is the phthalate-free standard which is our new feature. These phthalate-free products have all been formulated to meet the same specification (FR, anti-microbial and all physical properties) as our prior products and hence there is no change in the fabric’s appearance or performance.

We hope you agree that this change will be of significant benefit by keeping your Vintex V-Care and SoffTICK coated textile components in compliance with all current and possible future regulations.

Note: This change does not apply to your Supreme 4-way stretch PU/knit fabrics, which as non- PVC products, have always been free of phthalates.

Domestically Fabricated Bed Pads and Guard Barriers are Safer – The Facts Speak

If your medical facility has been weighing the options between bed pads, pillows, bibs and/or other fabric based products for your patients, safety should be in the forefront of your evaluation criteria. Durability, comfort, cost and other factors also are important in evaluating these products. Fabrication materials however should not be discounted as many offshore textile companies are not subjected to high North American standards of consumer product safety and quality.

79% of offshore products contain lead in excess of North American Standards.

83% of offshore pads contain other heavy metals including cadmium and mercury in excess of North American Standards.

100% of offshore pads contain Phthalate plasticizers, in most cases DEHP (DOP) which is subject to a permanent ban under the CPSIA guidelines in certain products.

92% of offshore pads either delaminate or leak well before 150 laundry cycles.

Vintex Upgrades Barriers to be Certified Lead, Heavy Metal and Phthalate Free

In response to growing concerns in healthcare and institutional settings over certain harmful chemical compounds, Vintex introduces “Safe Guard Barrier Systems” – the healthier, safer barrier choice. All Vintex Safe Guard Barrier fabrics are certified by an independent third party lab to be free of lead, cadmium, mercury and phthalates. Certified Safe Guard Barrier Systems.